Category Band Heaters

Tubular Band Heater

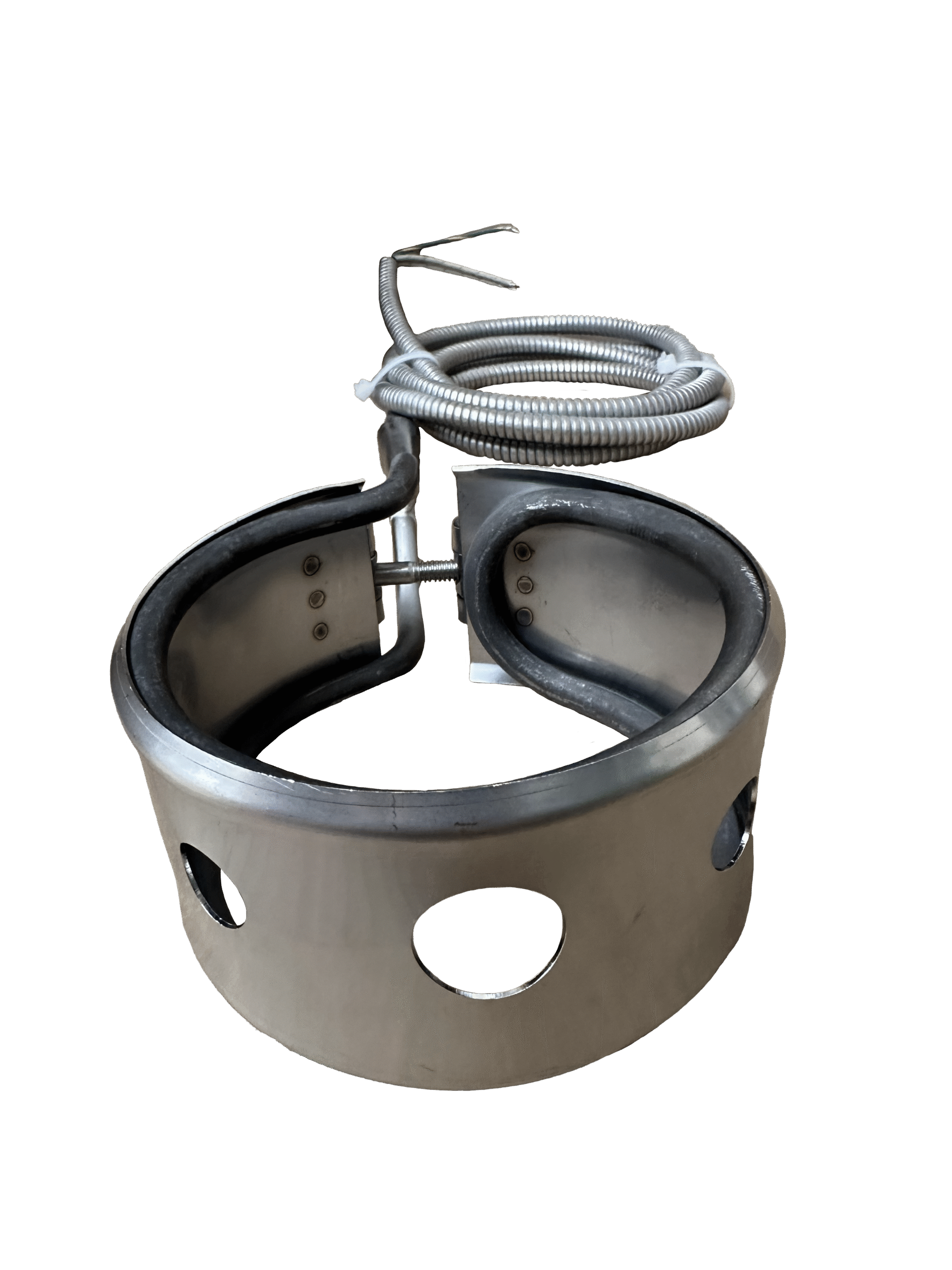

Tubular Band Heater

Tubular Band Heaters are designed for demanding applications where high heat, durability, and precise fit are critical. Their rugged tubular heating element construction ensures long service life, even in environments with contamination, air cooling, or mounting constraints.

- Operating Temp: Up to 1200°F

- Designed for narrow areas (1½″ wide or less) and bolt clearance zones

- Contamination-proof with armored lead options

- Ideal for air-cooled and high-cycle extrusion processes

Applications

- Narrow areas (1½″ wide and less) where concentrated heat is required

- Mounting areas with bolts or holes in the heated cylinder

- Air-cooled cylinders

- Areas exposed to contamination where sealed heater and cable connections are essential

- Dies and front-end heat in extrusion processes

Features

- Contamination-proof construction

- Long service life under tough conditions

- Ideal for narrow heaters with bolt clearance

- High efficiency and uniform heating

Design and Construction

- Size: ID (minimum .75”), Width (minimum .5”)

- Electrical: Watts, Volts- Ideal Watts per Square Inch 35 or less, 3 Phase

- Lockup: Flange, Extended Flange, Strap, Key, Barrel Nut, Compression Springs, Quick Release Latch

- Mechanical: Add Holes, Notches, Built in Thermocouple or Thermowell

- Lead Options: Flexible Fiberglass Leads, Armored Cable (BX), Braided Wire

- Other Power Supply Options: Screw Terminals (with or without ceramic caps), Plug, Housin

Applications

- Narrow areas (1½″ wide and less) where concentrated heat is required

- Mounting areas with bolts or holes in the heated cylinder

- Air-cooled cylinders

- Areas exposed to contamination where sealed heater and cable connections are essential

- Dies and front-end heat in extrusion processes

Features

- Contamination-proof construction

- Long service life under tough conditions

- Ideal for narrow heaters with bolt clearance

- High efficiency and uniform heating

Design and Construction

- Size: ID (minimum .75”), Width (minimum .5”)

- Electrical: Watts, Volts- Ideal Watts per Square Inch 35 or less, 3 Phase

- Lockup: Flange, Extended Flange, Strap, Key, Barrel Nut, Compression Springs, Quick Release Latch

- Mechanical: Add Holes, Notches, Built in Thermocouple or Thermowell

- Lead Options: Flexible Fiberglass Leads, Armored Cable (BX), Braided Wire

- Other Power Supply Options: Screw Terminals (with or without ceramic caps), Plug, Housin

Talk to Industrial Heater

01

Ready to stop settling and get the heater bands you actually need?

02

Ready for a quote in less

than 12 hours?

than 12 hours?

03

Then reach out. Industrial Heater will get you what you need as fast as you need it.