Ovens and Furnaces

IHCO ovens are high-efficiency heating modules built for curing, wire processing, sintering, and other high-temp industrial processes.

- Energy-efficient: High watt density ensures optimal energy use.

- Even heat distribution: Uniform heating for various applications.

- Versatile installation: Can be installed vertically or horizontally.

- High maximum operating temperature: Up to 1000°F (Keyhole design) and 1400°F (Rectangular design).

- Rugged construction: Built for long service life, with high durability for industrial and commercial environments.

- Preheating

- Insulation curing

- Wire stripping

- Printing

- Enameling

- Overcoating

- Tape sintering

- Lacquering

- Plastics

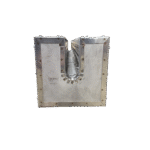

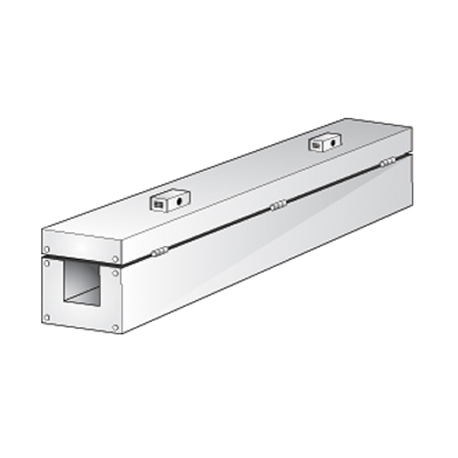

Keyhole Design

(Ceramic-Insulated Heating Elements)

Standard Construction

- 5000 watts

- 220 or 440 volts 3-phase

- 3 ceramic-insulated heating elements

- 1” x 4 1/2” slot

- 3 thermowells (1/8” NPT)

- Rust-resistant sheath

- Overall dimensions: 8” x 8” x 60”

Electrical Variations:

Custom maximum watts based on size.

- 240, 480, 240 3-phase

- or 480 3-phase options.

Mechanical Variations:

Custom size options and additional features for various industrial needs. Available with hinged slot covers.

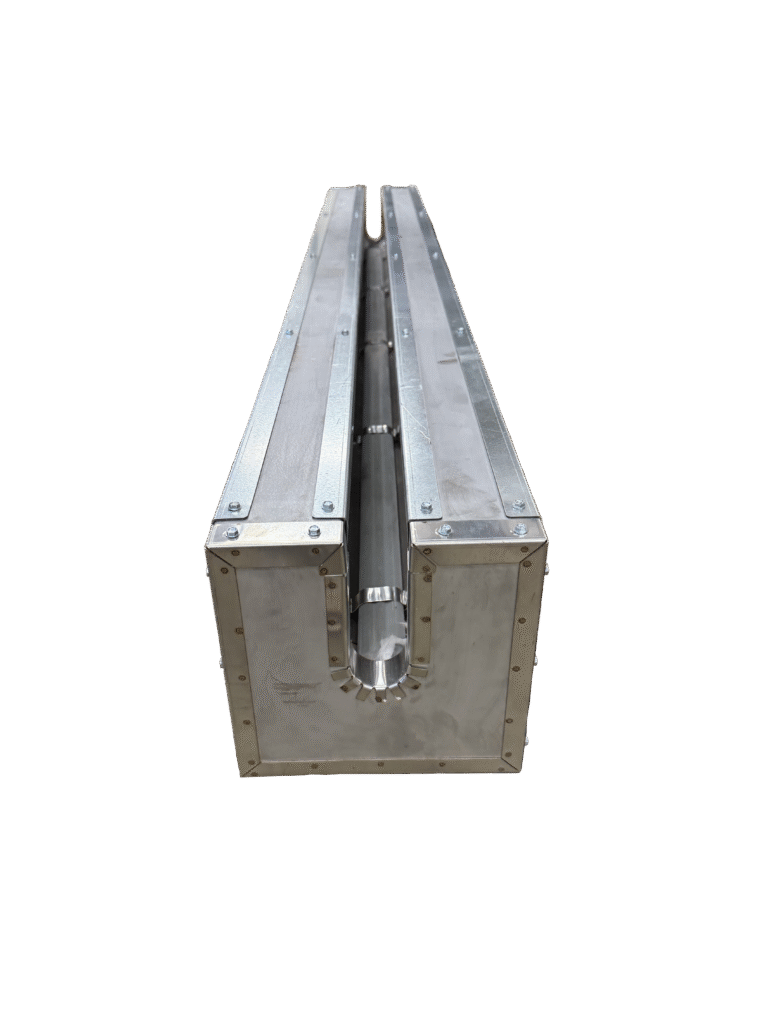

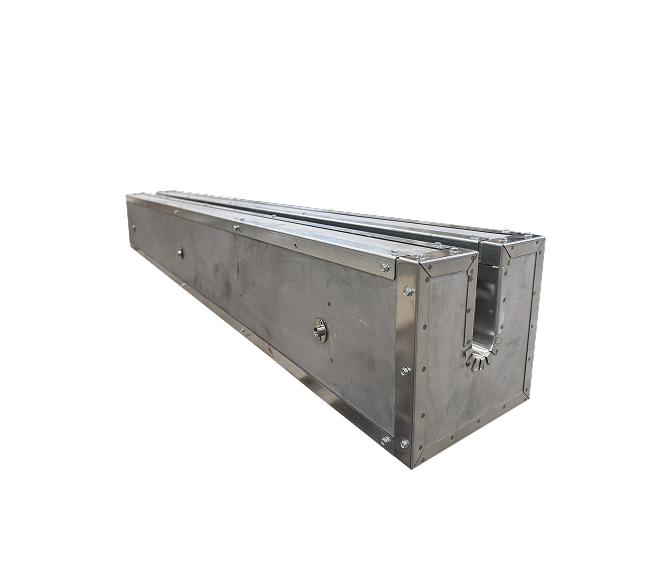

Rectangular Design

(Ceramic-Insulated Heating Elements)

Standard Construction

- 14,400 watts

- 460 volts 3-phase

- Multiple thermowells

- Ceramic heating elements

- 240 or 480-volt, 3-phase

Electrical Variations:

- NEMA housing types (1, 4, or 7)

- Tubular or quartz heating elements

- Multiple heat zones for precise temperature control.

Mechanical Variations:

Slot size and mounting arrangements to suit specific industrial applications. Aluminized or stainless steel sheathing. Temperature control with optional thermocouple location.